Freewheel — Destructive Removal

This article will discuss removing freewheels that have no removal tool option. This will be useful if the wheel is to be reused, but it will effectively destroy the freewheel. For wheels that are damaged with these types of freewheels, it is best to simply replace both the complete wheel and freewheel.

Procedure

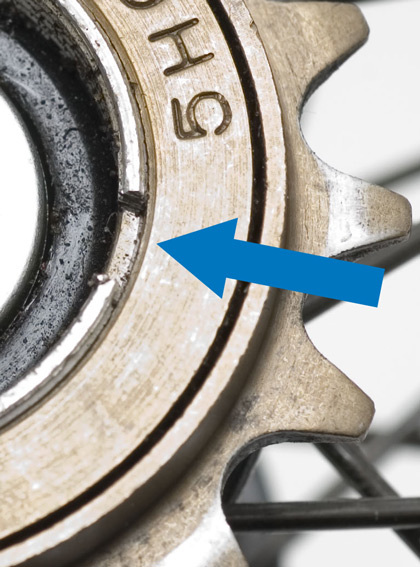

There are also current models of freewheels that do not have an adequate design for removal. If the image below, the freewheel has two very narrow and shallow notches that do not allow enough purchase for a tool. In the image below, removal would likely result in ruining the tool, the freewheel, or both.

Freewheels are ratcheting mechanisms with an inner and outer body. The inner body is threaded to the hub shell with right-hand threads. The sprockets are fixed to the outer body. Ball bearings allow the two body parts to rotate, while pawls and teeth in the body allow it to freewheel and then drive when the pedals are turned. The process below takes the freewheel apart for removal. It is very difficult to reassemble the freewheel successfully, so the freewheel is simply replaced.

The process of destructive freewheel removal is below:

- Remove the wheel from the bike, and remove the quick-release skewer or axle nuts (if non-quick-release type).

- Inspecting freewheel carefully. It is best to use the correct tool when available. See Determining Cassette / Freewheel Type for various Park Tool options.

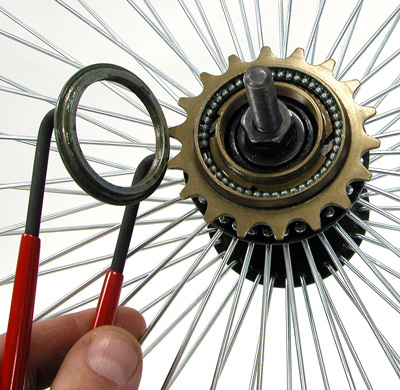

- Inspect freewheel for bearing cone. The cone will typically have pin holes. Use a pin spanner such as the SPA-2. The cone of the freewheel is a left-hand thread. Turn it clockwise to remove. The cone is typically very tight. Hold spanner snug to freewheel while turning. Alternatively, it is possible to use a small tipped punch and hammer to drive the cone clockwise.

Turn freewheel cone clockwise

Multiple gear freewheel also use cone with pin holes

- Remove cone completely. Inside will be ball bearings, pawls and springs.

- The ball bearings and pawls should now be removed. Lift the outer body of the freewheel off. Bearing will fall out. Inner body is now exposed.

- The inner body is threaded clockwise onto the hub shell. Look on inner body for two flats created by pawls. Grab the body firmly on these flats in a vise and turn wheel counter-clockwise.

- Dispose of the freewheel parts and install a new one.